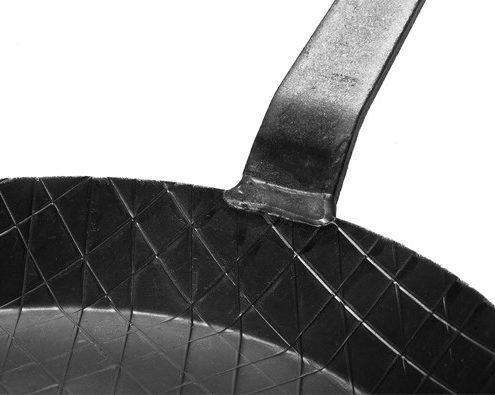

We’ve added some cool new stuff to our webshop! Forged iron Turk pans! The Turk pans are made in an interesting way. They produce them from one piece of iron. The process provides it of a seamless handle, an uniquely formed surface, and a very very fine quality..

Forged iron

The forged iron skillet has a continuous grain throughout, which comes from heat shaping (the process of heating at 1000 degrees C, then striking the metal with a hammer until it has the intended shape). The continuous grain of the iron makes the pan get hot faster than cast iron, and it stays hot, allowing food cooking on its surface to stay tender inside and form a crispy outer skin. This makes it an ideal pan for cooking meat!

Forged iron is also longer-lasting than cast iron, which is formed by pouring hot iron into a cast mold. If you drop a cast iron pan, it can break. Forged iron won’t!

Many recipes that call for roasting a dish in the oven will also mention the alternative use of an iron pan, for which the forged fry pan also works. It can all go right from the stovetop to the oven in this pan. And after that’s done, you can still put it back in the oven and use it again. And… That’s not all.. The Turk Pan with the bent hook handle (see the picture below) fits perfectly inside a closed Big Green Egg Small and bigger of course. So.. If you want to stew, use the Turk Pan with the bent hook handle. If you want to grill or bake, you can choose which one you prefer!

How to use

Iron is very simple to maintain. Basically, with a brand new iron pan, you prepare the pan for cooking by seasoning it, after which cleanup and soap will not be necessary. And if kept well, you’ll be passing it on to your grandkids.

A brand new iron skillet requires simple start care before you’re ready to cook, and a few rules of maintenance in order to make the pan last forever (which it really can). Here are the things you should know:

Never put the pan in the dishwasher or run cold water on the hot pan. This can shock the pan and cause fissures or even warp the pan. After use, allow it to cool slowly before rinsing with hot water.

As you heat the pan, the handles will become very hot! Use caution and always make sure you have an oven mitt or towels to cover the handles when you’re cooking.

How to care

The forged iron skillet only requires soap once in its life: and that’s when it’s brand new, right before you season it. The seasoning process is necessary. It protects the pan from rust and creates a nonsticky surface.

-Starting with a brand new, unseasoned skillet, wash the pan with soap. You can use simple dish soap. After this. Never wash it with soap again.

-Rinse the skillet with hot water to remove all the soap.

-After cleaning, make sure the pan is completely dry and smooth. You can heat it up on the stovetop if you want to ensure all moisture has been removed.

-Using cooking oil such as soybean, safflower or canola oil (don’t use low-smoke oils like olive or butter), apply it over every part of the skillet.

-Bake. Set the oven 350-400 F and place the cookware upside down on the top rack of the oven. Bake the cookware for at least an hour. You can place aluminum foil underneath the pan to avoid drippings getting on the heating element. Then turn off the oven and allow the cookware to cool (for several hours) to room temperature in the oven.

– Store. Put in a cool, dry place. Thinly coat the cookware with cooking oil in-between uses to maintain seasoning.

If your pan comes with a coating, simply wash it with warm water and a bit of soap before first use. This is an all-natural olive oil coating, which protects your pan from rust. Please note that the olive oil coating can also cause some streaks to appear in the surface – these will not impact the pan’s use in any way. Pans without a coating may have some white or silver spots present, as a result of the hot-forging process. These also have no impact on the quality of the pan, simply season it, then it will be ready for use.

Production & design

Since 1857, Turk has been manufacturing “Open-die hot forged” – formerly also called “handforged” – pans out of one piece, for skilled cooks and chefs who know their excellent characteristics and do not want to do without their advantages.

The company started with Albert Karl Turk, who installed a hammer plant on the mill of his father-in-law. Shovels and pans were manufactured here using the sledgehammer and the products became well known beyond the local region where they were produced. Two world wars and a serious fire later, the business was passed down to Hans-Peter Turk, a fifth generation Turk who employs 40 craftsmen to make 1,000 items a year.

Of the 40 employees, there are just 3 blacksmiths who forge the pans. At 1000 degrees Celcius, the handle of the pan is first stretched from a block of iron, then the pan body is spread. With a heavy hammer, the pan is beaten out to meet its intended shape. To make one pan, there are ten steps involved of heating and shaping.

The whole pan is considered a piece of art by the metal craftsman who works it, and every pan comes out a unique item.